Brew FAQs

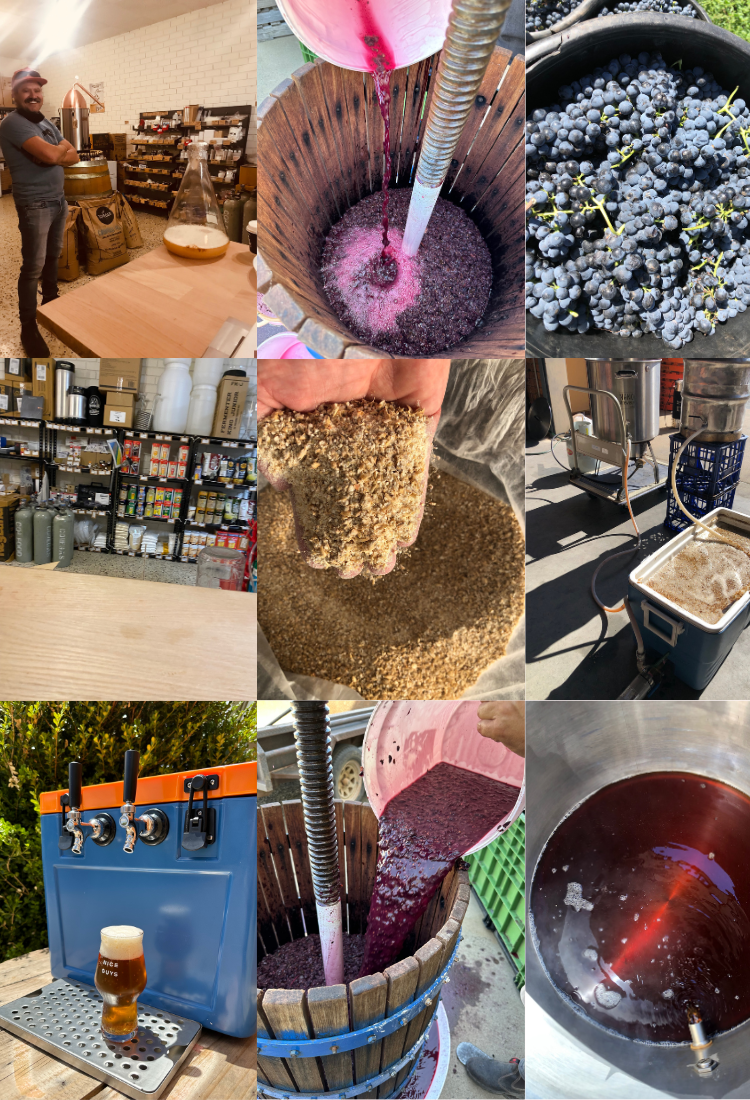

Brewing FAQ (1) - Ingredients

Good news, most malts are able to be substituted with equivalents. Be sure to pay attention to colour (EBC), region and tasting notes when choosing grains for your recipe.

If in doubt, feel free to send your recipe through to megan@grainmother.com. We will review through and advise you. ASAP promise!

You can also refer to our Grain Guide HERE.

Great question, we offer coarse crush which is suited for both single vessel system, three vessel system or BIAB all grain. We have our grain mill set at the perfect gap.

HOPS

We vacuum seal our hops as soon as we pack them to ensure delicate aromatic oils are not oxidised. After opening, we recommend you pack the hops you don’t use with the air squeezed out and resealing them if you have a sealing machine or in a zip lock bag and store them in the freezer.

GRAIN

We recommend storing your grain in air-tight containers in a cool, dry place to keep pests away.

Brewing FAQ (2) - Fermentation

Absolutely not. It works just fine with just sprinkling the yeast on top, and it’s certainly easy. On the other hand, many experts agree that yeast should be rehydrated in a small amount of water before pitching. Their reasoning is certainly sound, but when in doubt, follow the directions on the yeast packet or visit the manufacturer website for more information.

An Airlock isn’t a great tool for monitoring fermentation. Temperature changes, dry hopping, and settling of yeast can all cause an airlock to bubble – none of these are indicators of fermentation. The only way to be sure a fermentation is progressing is to monitor the SPECIFIC GRAVITY with a hydrometer. Not only will this help you to work out the alcohol-by-volume (abv) of your beer, it will also show you definitively that your beer has finished fermenting and is ready to be packaged. Monitor the specific gravity of your brew with a hydrometer and bottle/keg your beer when it is stable (no change) over 24-48hrs

If you are using a hydrometer and you do not notice any yeast activity or change in specific gravity, make sure of the following:

You’ve fermented within your yeast’s temperature range,You’ve used enough yeast (we recommend 2 or more sachets for worts over 1.050 OG)Your wort is fermentable. Worts with a very low pH, with excessive adjuncts, a high proportion of dark malts, or mashed too hot may all struggle to ferment.

We also recommend to pick up your fermenter with the side handle, give it a gentle swirl. This will help to stir up the yeast which may give some activity in the airlock after 24 hours (do not open the lid)

Hydrometer reading off– Keep in mind that a hydrometer is calibrated to a certain temperature, usually 15 or 20˚C. For best results, chill the sample to the appropriate temperature and/or use a hydrometer temperature correction calculator to make adjustments.

Added water to fermenter without regards to gravity– Many homebrew recipe kits instruct the brewer to top off to five gallons, but if for some reason you didn’t get all the malt extract out of the can or lost some volume in the process, adding this much water may dilute your beer below the target starting gravity. For best results, take a gravity sample before diluting and use a dilution calculator to figure out exactly how much water to add in order to hit your target SG.

We recommend finding a cool, dark spot where temperature is also consistent throughout fermentation. For Ales you should aim to ferment between 18 & 22°C. The cooler the brew, the more slowly it ferments and the lower the chance you have of “off” flavour production. Even if the temperature does sneak up on those hot summer days, it will still be drinkable but drier than usual, and will potentially have a “yeasty” flavour known as “yeast stress” since the heat causes faster fermentation than yeast desire.

As for lagers, fermentation is more tricky, and will require you to invest in a fermentation fridge or convert your old fridge into a fermentation chamber using a temperature controller. Here you should aim to ferment at 13°C for 2-3 days. Ramp up the temperature to 20°C over 10 days. Slowly cool it down to 1°C over a space of one week. Keep it at 1°C for 1-2 weeks. Final gravity for most lagers should be around 1.006 or 1.008. Keg or Bottle.

Brewing FAQ (3) - Bottling and Equipment

When bottling homebrew, carbonation occurs by giving the yeast a small amount of extra priming sugar to consume. After capping, the yeast will eat the sugar and produce CO2, but since the bottle is sealed the carbonation will have nowhere to go but into solution in the beer. In order for the yeast to do their job, they have to have ideal conditions, in particular, a temperature range that’s warm enough for them to work. This usually means about 21˚C. If the beer is stored in a cold basement or refrigerator during this phase, the yeast won’t carbonate the beer or may do so very slowly. Make sure the bottles are in a warm room and give them some more time.

The answer may be as simple as the brew being over carbonated. In instances where the beer is bottled before the fermentation process is complete, the carbon dioxide can build up enough pressure to cause the bottle to explode.

Thus, we recommends:-

Use carbonation drops: The drops are designed for longnecks and stubbies.

Use a sugar measure scoop: This scoop provides the right amount for stubbies, pints and longnecks.

Bulk prime: There are many bulk priming calculators online where you can enter the details of your brew and it will tell you how much sugar you need to prime the whole batch.

No difference in the quality or taste of your brew. Your beer will ferment, and carbonate the exact same way.

Glass will last a lifetime (excluding breakage). PET bottles and HDPE fermenters will last a long time if well cared for, however aggressive cleaning will scratch plastic surfaces and plastics left in harsh conditions (full sun, extremes of temperature) will degrade and shorten lifespan. Lids, o-rings, grommets etc can be replaced to recondition plastics.

Excellent question, we say patience is a virtue.

The short answer is about 3-4 weeks.

Fermentation takes about 5-10 days. During these times, the yeast is working hard to convert sugar to alcohol. If you do not allow the yeast to finish their job, it can open your brew up to other problems such as bottle explosions and “off” flavours, which is a beer that just doesn’t taste as good as it should!

Bottle Conditioning takes about 2 weeks. However the longer the beer is in the bottle, it tends to improve the flavour of the beer. Try some at 2 weeks, but see if you can detect an improvement at the 3 or 4 week mark.

Happy Brewing!

Recipe Development

Absolutely, this is part of a service we provide at Grainmother. Name us the following:-

1) Style of beer

2) Batch size

3) System set up - BIAB/Single Vessel/Triple Vessel System?

4) ABV

Absolutely, pop us an email. And we will get back to you.

Any question?

If we still haven't answered your question, you can contact us below and we will get back to you as soon as possible.