Description

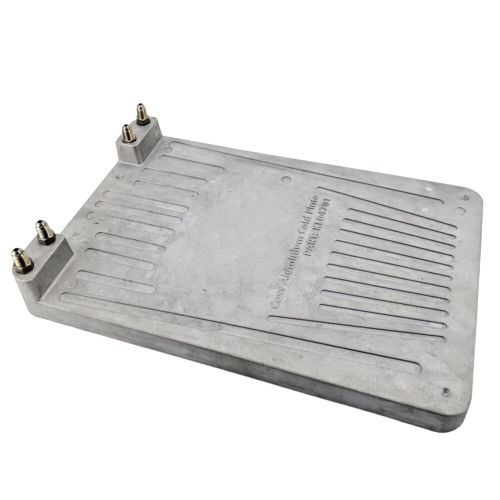

Specifications

- Size: 26cm x 38cm x 2.5cm Thick

- 6.5kg Aluminium Casting with large thermal mass

- 5 meters OD x 4mm ID diameter per 304 stainless tube

- Includes 4 mounting holes if you want to install your plate

Performance Charecteristics

With 20C ambient beer temp and flow rate through the cold plate of 300ml/10 seconds and 70% coverage of ice in contact with the cold plate you will be able to reduce the temperature of the liquid as it exits the cold plate to below 4C with a single pass through this cold plate.

If your beer is warmer than 28C we would recommend either slowing your flow rate through the cold plate or alternatively having the beverage pass through the cold plate twice.

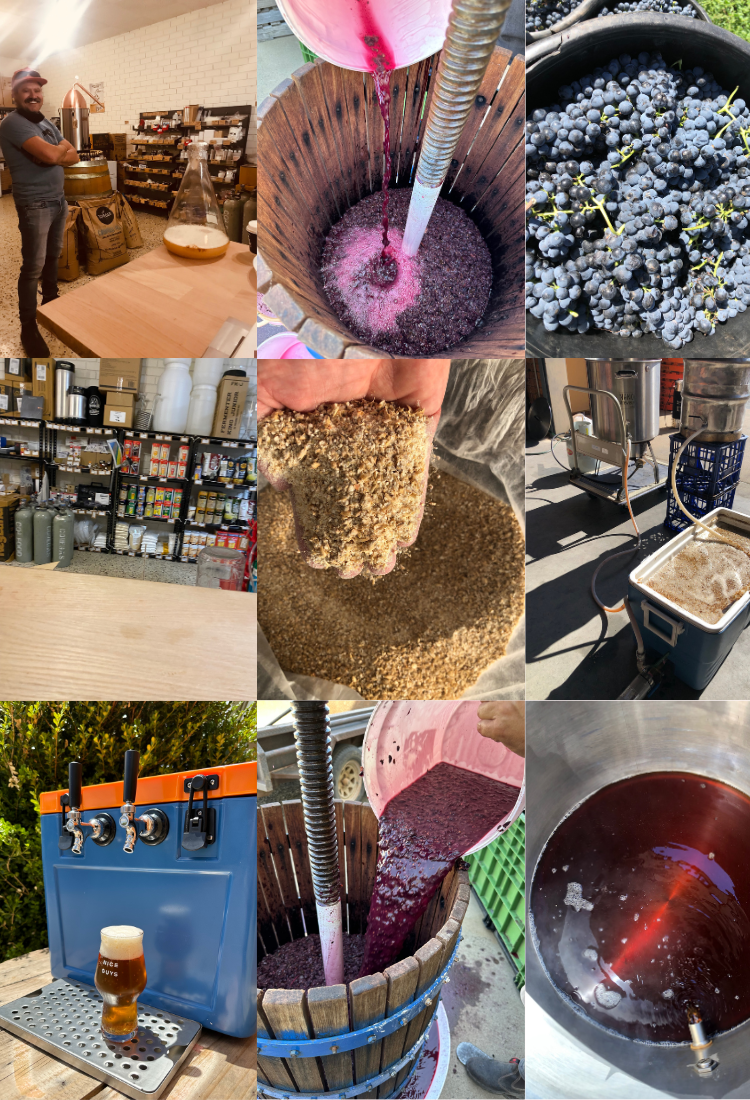

The most common way to use this type of cold plate is to stick it into the bottom of an eksy, drill holes through the esky wall and then glue the cold plate to the floor of the esky with some polyurethane sikaflex.

If you dont want to drill holes in your esky another options is to make a cooler box collar like this. One of our customers was kind enough to show us the collar that he made.

The nice thing about this design is that you don't have to drill holes in the cooler and you can remove the collar and cold plate at a later date.

Troubleshooting:

If you get frothing it will generally be caused by one of two things which are easy to solve:

1. If you look at the beer line between the cold plate and your keg (before the beer has gone into the cold plate) and you have bubbles or air pockets in your beer line then your dispense pressure is too low. Increase your pressure at the keg to ensure the CO2 is not coming out of solution.

2. If you measure the measure the temperature of the beverage as it comes out of the tap it should be below 5C. If the temperature is higher than 5C then:

a) Make sure you have complete coverage of ice in the eksy/cooler box

b) Decrease the flow rate of product through the cold plate so you the beverage has more contact time as it passes through the cold plate.

Over Carbonation WARNING:

As these cold plated require considerable dispense pressures (20-30psi) your beer will gradually absorb more carbonation if you are using pure CO2 to dispense the beer especially if your kegs are cold. If you are using CO2 to dispense your keg it will work fine for short periods up to 6-7 hours. If however you cease dispensing then disconnect the kegs and take the additional CO2 out of the head space of the keg before storing the keg. This will prevent additional CO2 absorbing into solution. If you are dispensing the kegs over multiple days we would recommend the use of nitrogen/CO2 mixed gas or straight nitrogen and this will prevent any over carbonation of your beer.